What Is Interior Architectural Film

Learn what interior architectural film is and how it transforms surfaces with stylish, durable finishes that offer a cost-effective alternative to traditional renovations.

This film is a multi-layer sheet made from engineered polymers. It has a printed or embossed design on the front and a pressure-sensitive adhesive on the back. Some films mimic wood or stone. Others offer matte colors, metals, or textile looks.

The surface may include protective coatings that resist scratches or fingerprints. The adhesive bonds when pressure is applied, so installation needs firm contact and clean substrates.

Key Properties of the Film

These films have a flexible construction. They bend around edges and cover long panels with one run. The adhesive activates under steady pressure, so good installation depends on clean surfaces and stable room temperature. Most films include a clear top layer that protects the printed pattern. This layer improves scratch resistance and keeps the design from fading under indoor light. Thickness varies by brand, but most interior grades fall within a thin range that helps them wrap corners without lifting.

Where the Film Is Used Indoors

Interior architectural film works in many rooms and across many types of properties. It refreshes surfaces without removing cabinets, hardware, or panels. It offers a wide choice of finishes, which makes it suitable for both homes and commercial buildings.

Commercial Environments

Businesses use this material when they want quick upgrades with limited downtime. Offices often wrap doors, counters, desks, wall panels, and elevator cabs. Hotels apply it on guest room doors, wardrobes, bedside tables, and lobby walls. Clinics and care centers use it because the smooth coating is easy to clean. Shops cover checkout counters, fitting rooms, and display units during overnight updates. Many commercial properties choose film because it keeps noise and dust low.

Residential Spaces

Homes benefit from the same strengths. Kitchens get new life when cabinet doors and drawer fronts are wrapped. Wood patterns, stone textures, and solid colors blend well with common styles. Bathrooms use moisture resistant grades on vanities and storage units. Bedrooms and living rooms use it on wardrobes, sliding doors, shelves, and media units. The film covers older laminate or wood surfaces that are still structurally sound but have cosmetic wear. It also suits rental properties because it avoids demolition and produces little debris.

Visual and Texture Options

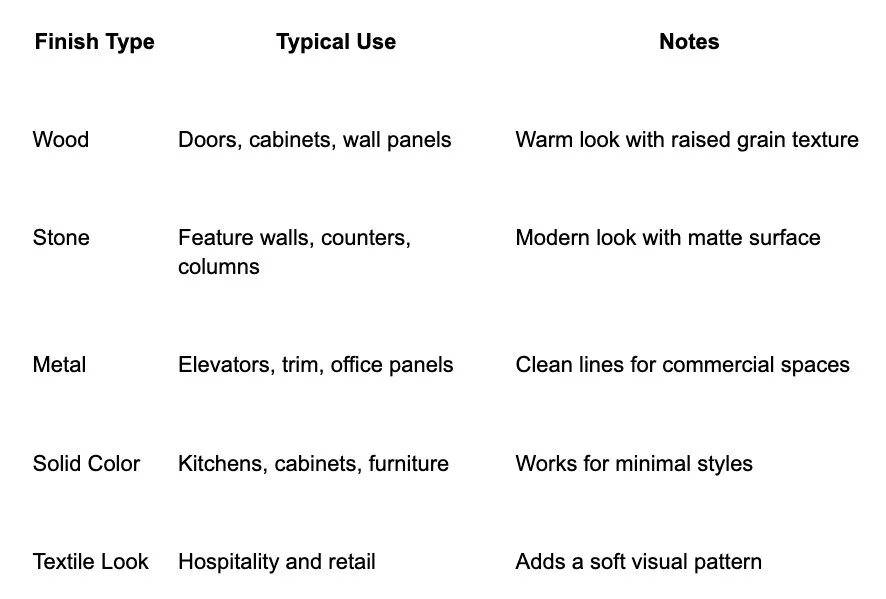

Manufacturers offer hundreds of finishes. Wood styles include oak, walnut, maple, ash, and darker tones with realistic grain texture. Stone designs mimic marble or concrete. Metal finishes have brushed or hammered looks. Solid colors range from soft neutrals to deep tones. Some patterns add fabric-like texture without the upkeep of real textiles. These options help match many interiors. Designers often combine two or three finishes in one project to create contrast.

A simple comparison helps illustrate the range:

Functional Performance

The film provides dependable performance in high-use areas. Its protective layer resists scratches from daily contact. Most grades tolerate normal indoor heat and humidity. Kitchens and bathrooms use them often when surfaces stay dry and smooth. The adhesive forms a strong bond when applied correctly. Edges stay secure when tools and primers are used as recommended. The surface cleans with mild soap and water. Abrasive cleaners are not advised because they can dull the finish.

Surfaces in busy hallways, reception desks, and meeting rooms hold up well when cleaned with soft cloths. Films with matte finishes reduce fingerprints. Gloss and metallic styles reflect more light but still resist marks. Many brands list a life span between five and ten years indoors. Actual life depends on use, cleaning habits, and exposure to moisture.

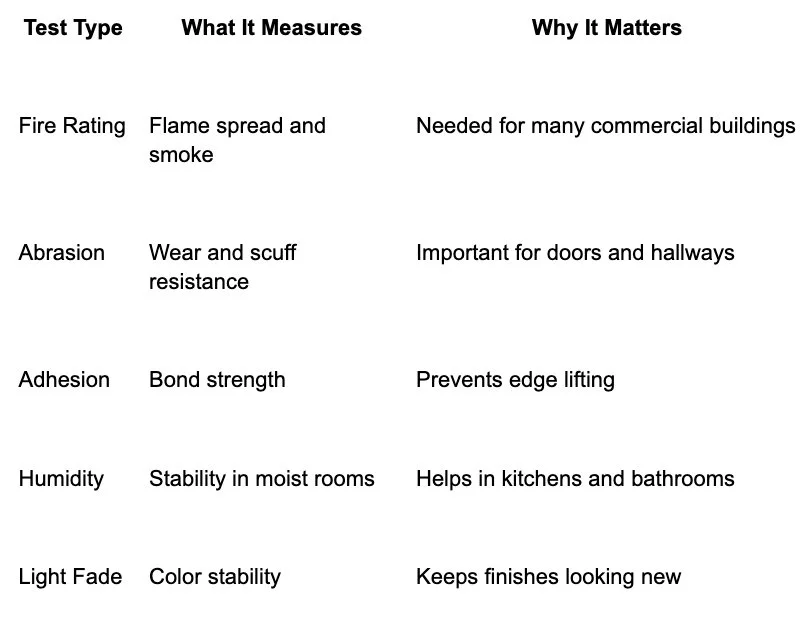

Testing and Certifications

Reputable films follow recognized safety and durability tests. Fire tests measure flame spread and smoke development. Abrasion tests measure wear under repeated rubbing. Adhesion tests measure how strongly the film bonds to surfaces. Humidity tests check how the film behaves in damp rooms. Colorfastness tests show how well printed designs hold their tone.

A simple breakdown helps:

Compatible Surfaces and Limits

The film works on many materials, including laminate, MDF, metal, PVC, and smooth painted surfaces. It needs a stable base. Loose veneers, swollen wood, or peeling paint must be repaired first. Sharp corners need sanding so the film can wrap cleanly. Curved surfaces can be wrapped if the curve is gentle. Very tight curves may need special heating methods or may not be suitable.

Porous surfaces absorb adhesive. They need a primer to create a stable bond. Textured walls are not ideal because the texture can show through. Films stick best to clean, dry, smooth substrates. Edges near sinks or showers must be sealed to prevent water from getting underneath.

Installation Process

Installation follows several steps. First, surfaces are cleaned with a non-oily cleaner. Any damaged areas are filled, sanded, and smoothed. Primers are applied to tricky edges or areas under stress. The film is measured, cut, and positioned. Installers remove the liner as they press the film onto the surface. Tools like squeegees help remove air. Heat softens the material so it can wrap around corners. Once fitted, edges are trimmed and inspected. The surface is ready for use after the adhesive settles, which may take several hours.

Simple step list:

Clean and dry the surface.

Repair chips, dents, or peeling areas.

Sand edges and high points to make them smooth.

Apply primer where needed.

Cut the film to size.

Apply with pressure.

Heat and wrap corners.

Trim edges.

Inspect and wipe.

DIY or Professional Installation

Small, simple pieces are possible for confident DIY users. Flat doors, drawer fronts, and smooth panels are manageable when patience and clean technique are used. Curves, deep edges, textured panels, and large sheets are more demanding. Uneven pressure, poor trimming, or incorrect heat can lead to lifting and bubbles.

Most projects benefit from a trained installer. Professionals handle repairs, surface prep, seams, curves, and tricky edges with accuracy. Interior architectural film installers like Profilms use proper tools and follow manufacturer guidelines, which protects the finish and helps the film last longer. This is the safer choice for kitchens, commercial spaces, and any project with heavy use.

Cost Factors

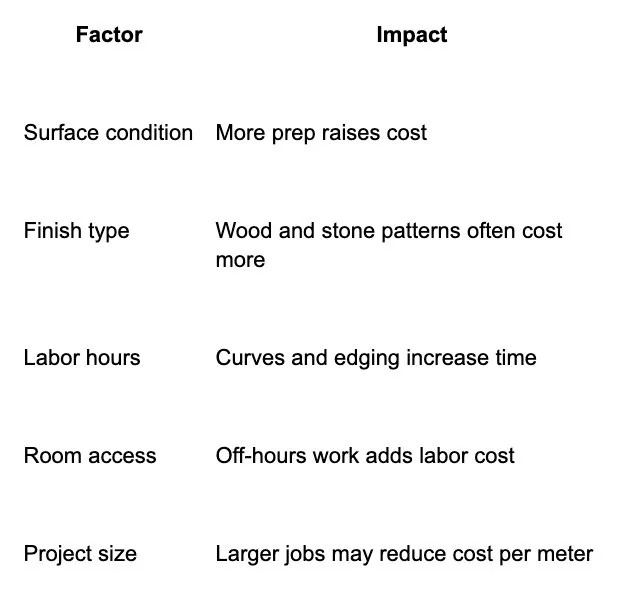

Costs vary based on several factors. Complex surfaces increase labor. Curved panels, deep edges, and worn substrates take more time. Material grade and texture also affect price. Some finishes cost more due to detailed embossing or special coatings. Large projects in commercial spaces may cost more because they require off-hours work.

A cost model might include:

Sustainability Impact

Interior architectural film supports low-waste renovation. It keeps existing cabinets and panels in place. This reduces demolition waste and shortens project timelines. Many owners use it during refresh cycles to extend asset life. Shipping and packaging waste are low compared to new cabinets or panels. Some brands offer PVC-free options. Films also help avoid the carbon impact linked to replacing large furniture or built-in units.

Care, Cleaning, and Removal

Cleaning involves soft cloths and mild soap. Strong solvents and abrasive pads are not recommended. The surface should stay dry and smooth. If a panel is damaged, it can be rewrapped without removing the entire installation. Removal is simple when the adhesive is warmed slightly. Most films peel away in sections with minimal residue. Any leftover adhesive cleans off with approved cleaners. Many owners choose removal when updating to a new finish.

Examples of Interior Architectural Film in Use

Small kitchens often use interior architectural film for fast makeovers. A set of outdated cabinets can be wrapped in a day. Stone-look finishes on counters or islands give a modern tone. Offices wrap meeting room doors and wall panels during weekend projects. Retail stores refresh fitting rooms and display tables overnight. Hotels change guest room doors to match new branding without replacing hardware.

These examples show how low disruption makes film a strong choice for occupied buildings.

FAQs about Interior Architectural Film

Can the film handle heat near stoves

Most interior films handle common kitchen heat. They should not touch active heat sources. A small gap from heat-producing units is advised.

Can it wrap tight curves

Gentle curves are suitable. Tight bends may need advanced heating or may not be possible.

How long does it last

Indoor use often reaches five to ten years, depending on cleaning and use.

Is it safe for commercial buildings

Many films hold fire ratings required for commercial interiors. Check the exact rating on the product sheet.

Do I need an electrician for some parts of the job

You may need one if the film goes around outlets, switches, or built-in lighting. An electrician can remove faceplates and secure wiring before the wrap.